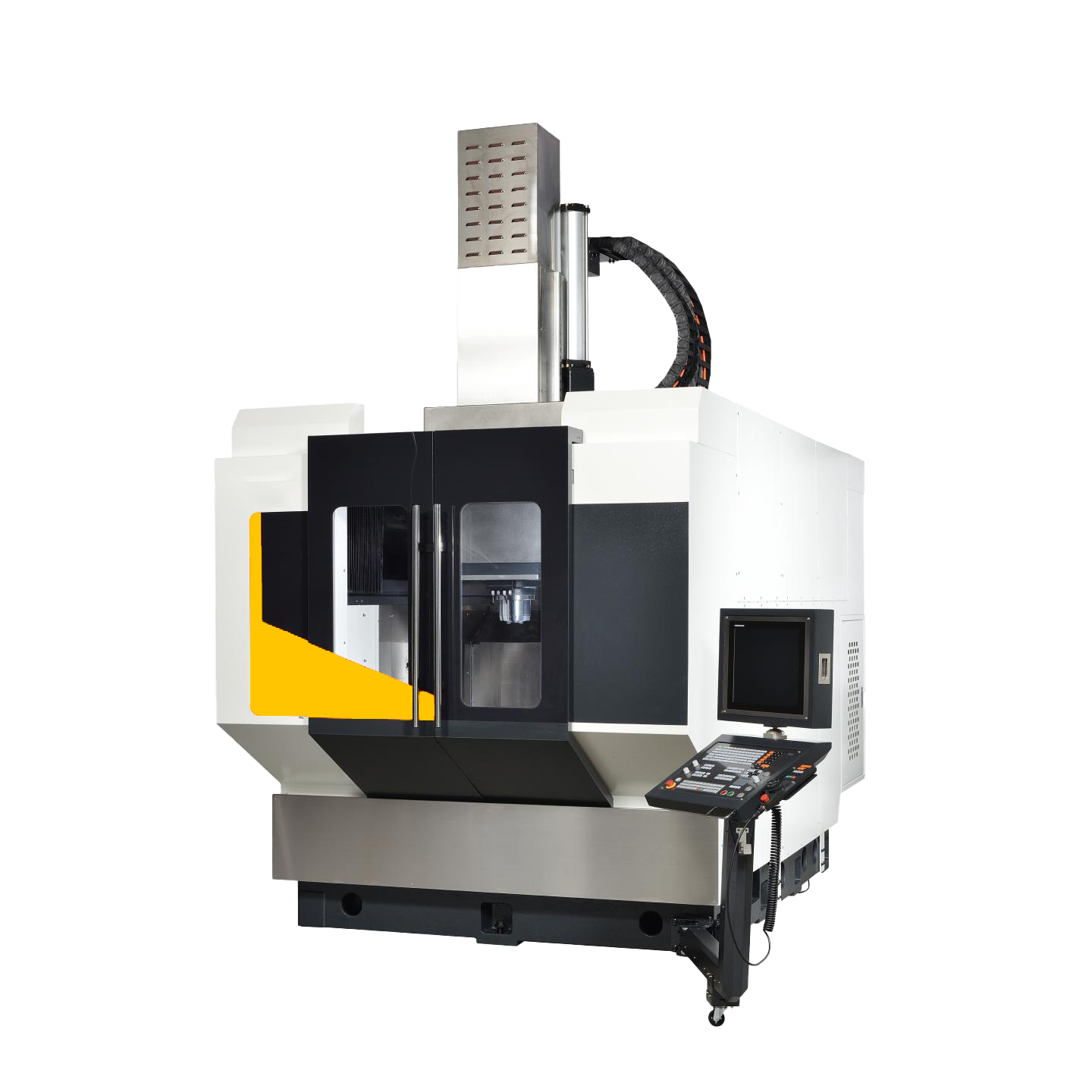

5-Axis Machining Centers

Experience unmatched precision and flexibility with Anderson CNC’s complete lineup of 5-axis machining centers. From the compact trunnion-style FUV series to the large-capacity FUV-T series— which integrates an extended X-axis and a secondary rigid table to enable seamless transitions between 3-axis and 5-axis operations—our solutions handle the most complex geometries with exceptional accuracy while maximizing floor space and machining flexibility.

5-Axis Product Series

Choose from our comprehensive range of 5-axis machining centers, each engineered for specific applications from precision medical components to large aerospace parts.

FUV 170-500 Series

Models: FUV-170 • FUV-200 • FUV-250 • FUV-320 • FUV-400 • FUV-500

Compact 5-axis trunnion-style machining centers ideal for precision components, medical devices, and complex parts requiring simultaneous 5-axis machining with A/C axis configuration.

FUV 650/720 Series

Models: FUV-650 • FUV-720

Mid-size 5-axis machining centers with B/C axis configuration featuring high-speed built-in spindles up to 24,000 RPM and large tool magazine capacity up to 204 tools for complex production.

FUV-800 Series

Model: FUV-800

Large-capacity 5-axis machining center with Ø800mm table and A/C axis configuration. Supports ISO 50 tooling for heavy-duty cutting with up to 1,200kg table load capacity for large aerospace and mold components.

FSV Series

Models: FSV-400 • FSV-500 • FSV-600 • FSV-700

Bridge-type 5-axis machining centers with built-in spindle and B/C axis configuration. Features large rectangular work area ideal for aerospace structural parts, molds, and complex surface machining with turning capability.

FM Series

Models: FM-410 • FM-500

Compact 5-axis machining centers with tilting trunnion table and A/C axis configuration. Designed for medical, dental, and precision components requiring fast tool changes and high accuracy.

FUV-T Series

Models: FUV-170T • FUV-190T • FUV-210T

Production-oriented 5-axis machining centers with twin ATC magazines (24×2 tools) and large rectangular work tables. Designed for high-volume aerospace and automotive production with B/C axis configuration.

5-Axis Technology Advantages

Our 5-axis machining centers deliver superior accuracy, flexibility, and productivity for the most demanding applications.

Simultaneous 5-Axis

True simultaneous 5-axis motion enables complex contour machining and undercut features in a single setup.

High-Speed Spindles

Direct-drive and built-in spindles up to 24,000 RPM for superior surface finish and productivity.

Precision Accuracy

±0.005mm repeatability with thermal compensation and high-rigidity construction for consistent results.

Direct Drive Rotary

Direct-drive rotary axes eliminate backlash and provide high-speed positioning with exceptional accuracy.

FANUC/Heidenhain

Industry-leading CNC controls with advanced 5-axis kinematics, RTCP, and toolpath optimization.

Flexible Configuration

Trunnion, bridge, and swivel-head configurations to match your specific application requirements.

Large Tool Capacity

Up to 204-tool magazines for extended unmanned operation and complex multi-part production.

Thermal Stability

Advanced cooling systems and symmetric designs maintain accuracy during extended operation.

Model Comparison

Compare key specifications across our 5-axis machining center series to find the right fit for your application.

| Specification | FUV 170-500 | FUV 650/720 | FUV-800 | FSV Series | FM Series | FUV-T Series |

|---|---|---|---|---|---|---|

| Configuration | A/C Trunnion | B/C Trunnion | A/C Trunnion | B/C Swivel Head & C-Axis | A/C Trunnion | B/C Trunnion & Rigid Rectangular Table |

| Table Size | Ø170 - Ø500mm | Ø650 - Ø720mm | Ø800mm | Ø400 - Ø700mm | Ø410 - Ø500mm | Ø650mm + (700×500 ~ 1100×500)mm |

| X-Axis Travel | 360 - 600mm | 620 - 720mm | 800mm | 1100 - 1250mm | 560mm | 1700 - 2100mm |

| Y-Axis Travel | 420 - 700mm | 520 - 600mm | 920mm | 600 - 700mm | 480 - 500mm | 540mm |

| Z-Axis Travel | 465 - 520mm | 460 - 520mm | 650mm | 535mm | 450mm | 460mm |

| Max Spindle Speed | 15,000 RPM | 24,000 RPM | 20,000 RPM | 15,000 RPM | 15,000 RPM | 18,000 RPM |

| Tool Capacity | 24 - 40 Tools | 32 - 204 Tools | 32 - 120 Tools | 24 - 40 Tools | 30 - 40 Tools | 24×2 - 32×2 Tools |

| Max Table Load | 30 - 300kg | 300kg | 1,200kg | 500 - 850kg | 200 - 300kg | 1,200 - 2,000kg |

| Rapid Traverse | 36m/min | 48m/min | 36-48m/min | 30-48m/min | 36-48m/min | 16m/min |

| Machine Weight | 4,500 - 8,700kg | 10,000 - 10,800kg | 21,000kg | 6,700 - 8,000kg | 7,400 - 7,700kg | 17,000 - 19,000kg |

Ready for 5-Axis Precision?

Transform your manufacturing capabilities with Anderson CNC's advanced 5-axis technology. Our expert team is ready to help you select the perfect machine for your application.

Fast Delivery

In-stock machines ship within 2-4 weeks

Expert Training

Comprehensive 5-axis programming training

US Support

Local service technicians nationwide

Warranty

Comprehensive coverage with extended options