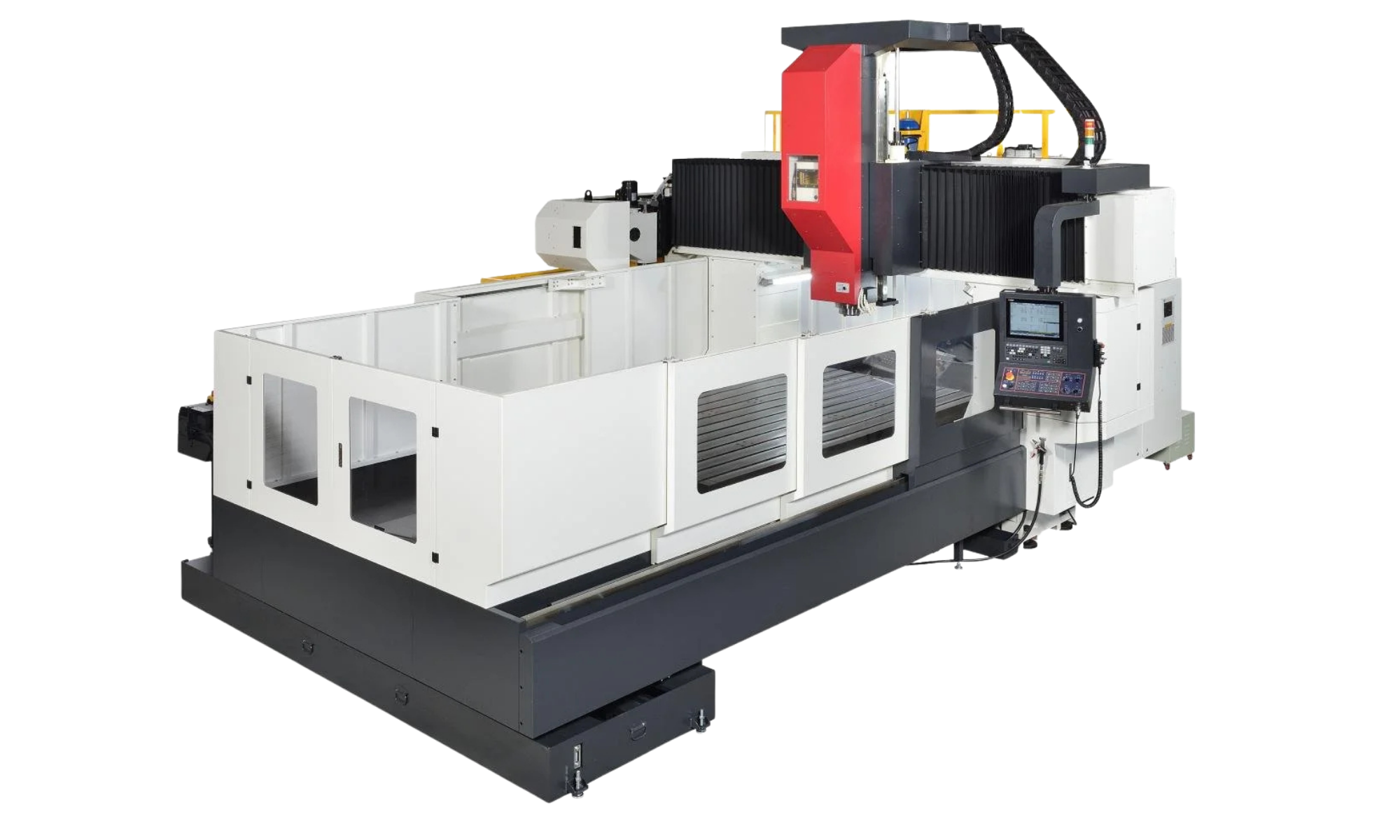

Double Column Machining Centers

Anderson CNC's Double Column series delivers exceptional rigidity and precision for large-scale machining operations. With X-axis travels from 1,700mm to 4,200mm and table loads up to 12,000kg, these machines are engineered for aerospace, energy, and heavy industrial applications.

Choose Your Series

Select the ideal Double Column machining center based on your workpiece requirements and production demands

14 Series

Models: 1417 • 1422 • 1432 • 1442

The 14 Series features 1,400mm Y-axis travel with X-axis options from 1,700mm to 4,200mm. Ideal for mold making, aerospace components, and large-scale production parts requiring exceptional precision.

17 Series

Models: 1722 • 1732 • 1742

The 17 Series expands machining capability with 1,700mm Y-axis travel and X-axis options from 2,200mm to 4,200mm. Features enhanced table capacity up to 12,000kg for heavy machining operations.

19 Series

Models: 1922 • 1932 • 1942

The 19 Series delivers 1,900mm Y-axis travel for even larger workpieces. Perfect for energy sector components, large molds, and structural parts requiring maximum machining envelope.

21 Series

Models: 2122 • 2132 • 2142

Maximum capacity 21 Series features 2,100mm column distance for the largest workpieces. Designed for aerospace structural components and heavy industrial applications.

Built for Performance

Every Double Column machine features precision engineering for demanding applications

Bridge Structure

Heavy-duty double column design provides exceptional rigidity for heavy cutting operations

ISO 50 Spindle

High-torque ISO 50 spindle handles aggressive roughing and precision finishing

Extended Travel

Up to 4,200mm X-axis travel accommodates extra-large workpieces

12,000kg Capacity

Heavy-duty tables support massive workpieces for industrial applications

Multi-Control Options

Choose FANUC, Mitsubishi, Siemens, or Heidenhain control systems

32-Tool ATC

Disk or chain-type magazine with arm-type changer for fast tool changes

Thermal Stability

Thermally symmetric design maintains accuracy during extended operation

Quality Assured

Every machine undergoes rigorous testing and certification before delivery

Series Comparison

Compare specifications across all Double Column series to find your ideal machine

| Specification | 14 Series | 17 Series | 19 Series | 21 Series |

|---|---|---|---|---|

| Y-Axis Travel | 1,400mm | 1,700mm | 1,900mm | 2,100mm |

| X-Axis Range | 1,700 - 4,200mm | 2,200 - 4,200mm | 2,200 - 4,200mm | 2,200 - 4,200mm |

| Z-Axis Travel | 900mm | 900mm | 900mm | 900mm |

| Column Distance | 1,400mm | 1,900mm | 1,900mm | 2,100mm |

| Max Table Load | 5,000 - 8,000kg | 8,000 - 12,000kg | 8,000 - 12,000kg | 8,000 - 12,000kg |

| Spindle Taper | ISO 50 | ISO 50 | ISO 50 | ISO 50 |

| Spindle Speed | 8,000 RPM | 8,000 RPM | 8,000 RPM | 8,000 RPM |

| Spindle Motor | 15/18.5kW | 15/18.5kW | 15/18.5kW | 15/18.5kW |

| Tool Capacity | 24/32 | 24/32 | 24/32 | 24/32 |

| Machine Weight | 15,500 - 18,000kg | 21,000 - 24,000kg | 22,000 - 25,000kg | 23,500 - 25,500kg |

Ready for Large-Scale Precision?

Our team is ready to help you select the ideal Double Column machining center for your production requirements. Get expert guidance and competitive pricing on machines engineered for heavy industrial applications.

Fast Delivery

Strategic U.S. inventory for rapid deployment

Expert Support

Factory-trained technicians nationwide

Custom Config

Tailored to your specific requirements

Competitive Pricing

Direct manufacturer pricing advantage