VMC Machining Centers

Discover Anderson CNC's comprehensive lineup of Vertical Machining Centers. From compact entry-level machines to heavy-duty production centers, our VMC series delivers precision, reliability, and performance for every application.

VMC Product Series

Choose from our comprehensive range of vertical machining centers, each engineered for specific applications from precision components to heavy-duty production.

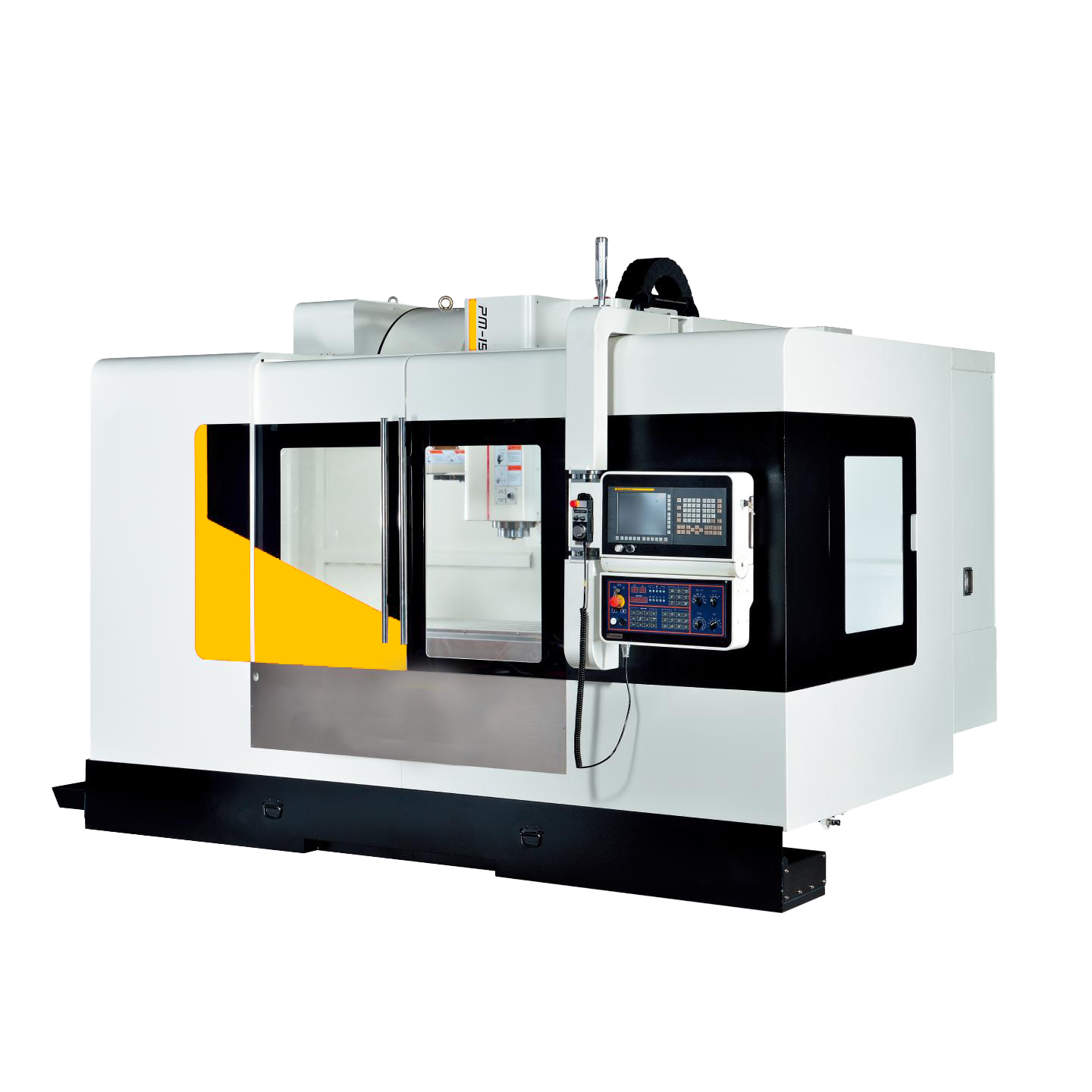

VMC 600/860/1160 Series

Models: VMC-600 • VMC-860 • VMC-1160 • VMC-1170

Versatile entry-level to mid-range vertical machining centers ideal for job shops and production environments requiring reliable performance and precision.

VMC 1100

Model: VMC-1100

The VMC 1100 delivers an optimal balance of capability and footprint, with 1100mm X-travel and 900kg table capacity for diverse machining applications.

VMC 1250/1350 Series

Models: VMC-1250 • VMC-1350

Extended X-travel options of 1250mm and 1350mm provide greater workpiece capacity with 700mm Y-axis travel for larger component machining.

VMC 1400/1500/1670 Series

Models: VMC-1400 • VMC-1500 • VMC-1670

Production-oriented series with X-travel from 1400mm to 1600mm and 1,500kg table capacity for demanding manufacturing environments.

VMC 1676/1876/2076 Series

Models: VMC-1676 • VMC-1876 • VMC-2076

Our flagship VMC series featuring 760mm Y-axis travel and X-travel options from 1600mm to 2000mm for large workpiece capacity.

VMC 1600/1800/2000 Series

Models: VMC-1600 • VMC-1800 • VMC-2000

Heavy-duty series with 1000mm Y-axis and 800mm Z-axis travel. ISO 50 spindle standard for aggressive material removal.

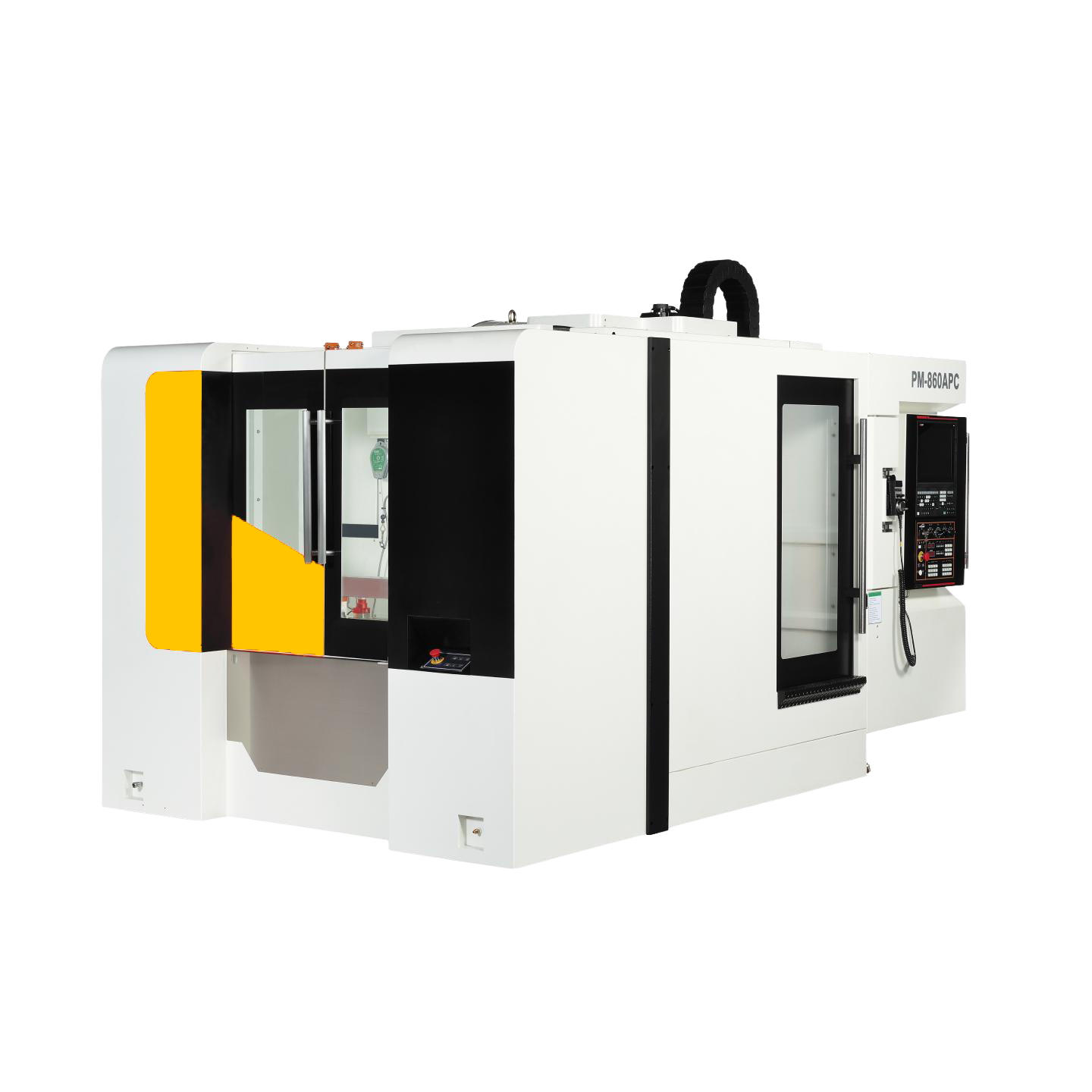

VMC 600/860/1100 APC

Models: VMC-600 APC • VMC-860 APC • VMC-1100 APC

Automated pallet changer series for high-volume production with 7-second pallet change time and 3,600kg lift capacity.

GM Series

Models: GM-1171 • GM-1371 • GM-1471 • GM-1590 • GM-1790 • GM-2090

Heavy-duty geared spindle series with ISO 50 taper for aggressive material removal and demanding heavy-cutting applications.

VMC Technology Advantages

Our vertical machining centers deliver superior accuracy, reliability, and productivity for the most demanding manufacturing applications.

FANUC Control

Industry-leading FANUC CNC systems with intuitive operation and advanced programming capabilities.

High-Speed Spindle

Direct-drive spindles up to 15,000 RPM with precision bearings for superior surface finish.

Precision Accuracy

±0.004mm repeatability with hand-scraped surfaces and precision ball screws.

Rapid Tool Change

Fast automatic tool changers with up to 40-tool capacity for reduced cycle times.

Heavy-Duty Construction

Meehanite cast iron construction with ribbed box-way design for maximum rigidity.

Linear Guideways

Roller-type linear guideways for smooth motion and extended service life.

Thermal Stability

Advanced cooling systems maintain dimensional accuracy during extended operation.

Quality Assured

100% inspected with laser calibration and comprehensive quality documentation.

Model Comparison

Compare key specifications across our VMC series to find the right fit for your application.

| Specification | 600/860/1160 | 1100 | 1250/1350 | 1400/1500/1670 | 1676/1876/2076 | 1600/1800/2000 | APC Series | GM Series |

|---|---|---|---|---|---|---|---|---|

| X-Axis Travel | 610-1,150mm | 1,100mm | 1,250-1,350mm | 1,400-1,600mm | 1,600-2,000mm | 1,600-2,000mm | 610-1,100mm | 1,100-2,000mm |

| Y-Axis Travel | 500-700mm | 600mm | 700mm | 700mm | 760mm | 1,000mm | 480-560mm | 710-900mm |

| Z-Axis Travel | 500-650mm | 600mm | 600-640mm | 600-640mm | 700mm | 800mm | 500-600mm | 610-850mm |

| Max Table Load | 300-1,000kg | 900kg | 1,200kg | 1,500kg | 1,800-2,400kg | 2,200-3,000kg | 200-300kg | 1,000-3,000kg |

| Max Spindle Speed | 8,000-15,000 | 8,000-15,000 | 8,000-15,000 | 8,000-15,000 | 8,000-15,000 | 6,000-10,000 | 8,000-15,000 | 4,000-6,000 |

| Tool Capacity | 24-40 Tools | 24-40 Tools | 24-40 Tools | 24-40 Tools | 24-36 Tools | 20-24 Tools | 24-40 Tools | 20-32 Tools |

| Rapid Traverse | 30-48 m/min | 30-48 m/min | 30-48 m/min | 30-48 m/min | 24-30 m/min | 15-24 m/min | 30-48 m/min | 12-20 m/min |

| Spindle Taper | ISO 40/50 | ISO 40/50 | ISO 40/50 | ISO 40/50 | ISO 40/50 | ISO 50 | ISO 40 | ISO 50 |

| Machine Weight | 4,300-7,800kg | 6,000kg | 7,000-7,500kg | 7,500-8,500kg | 8,700-10,000kg | 17,000-20,000kg | 5,500-7,500kg | 9,000-16,000kg |

Ready for Precision Performance?

Transform your manufacturing capabilities with Anderson CNC's advanced VMC technology. Our expert team is ready to help you select the perfect machine for your application.

Fast Delivery

In-stock machines ship within 2-4 weeks

Expert Training

Comprehensive operator and programmer training

US Support

Local service technicians nationwide

Warranty

Comprehensive coverage with extended options