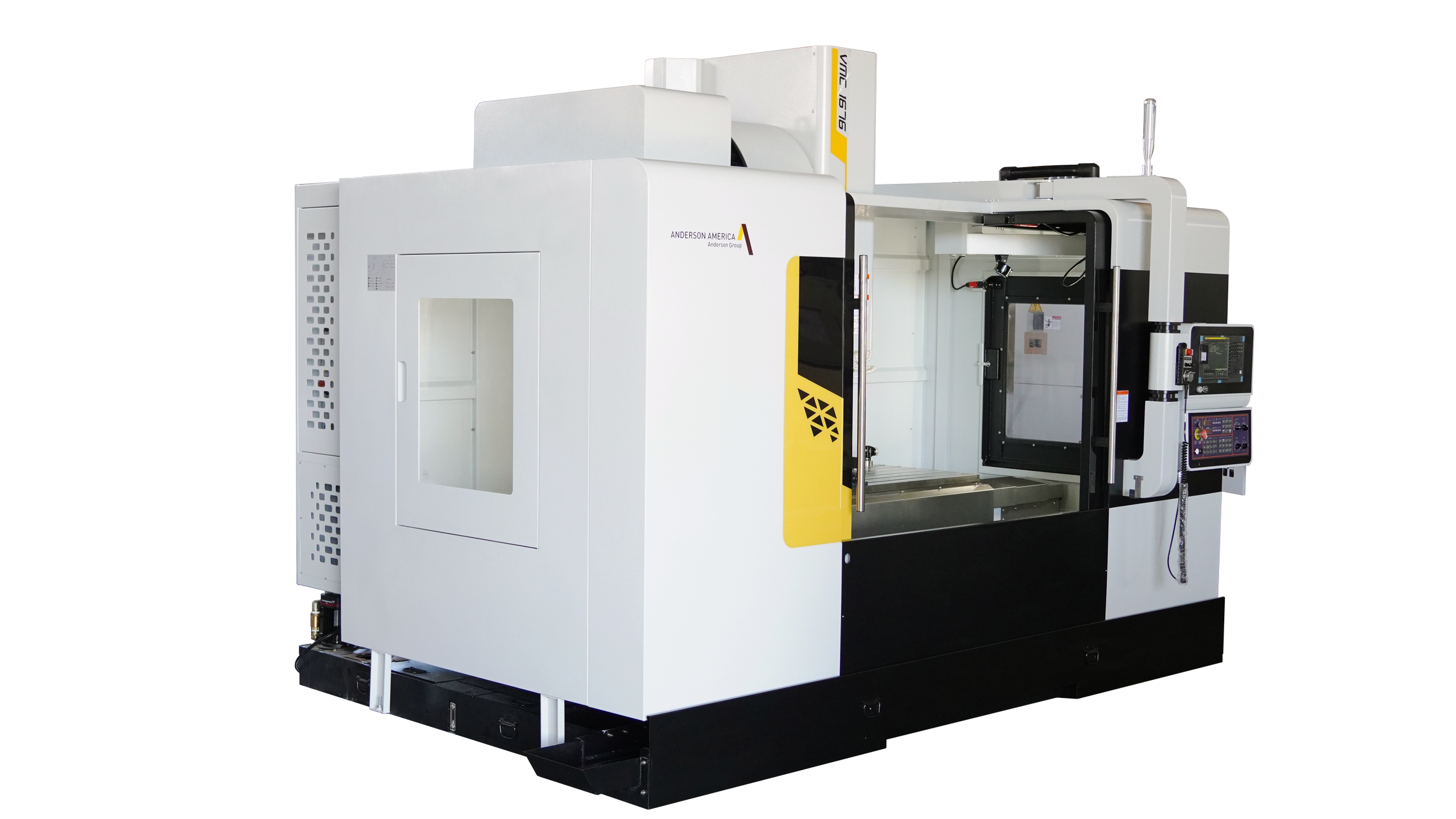

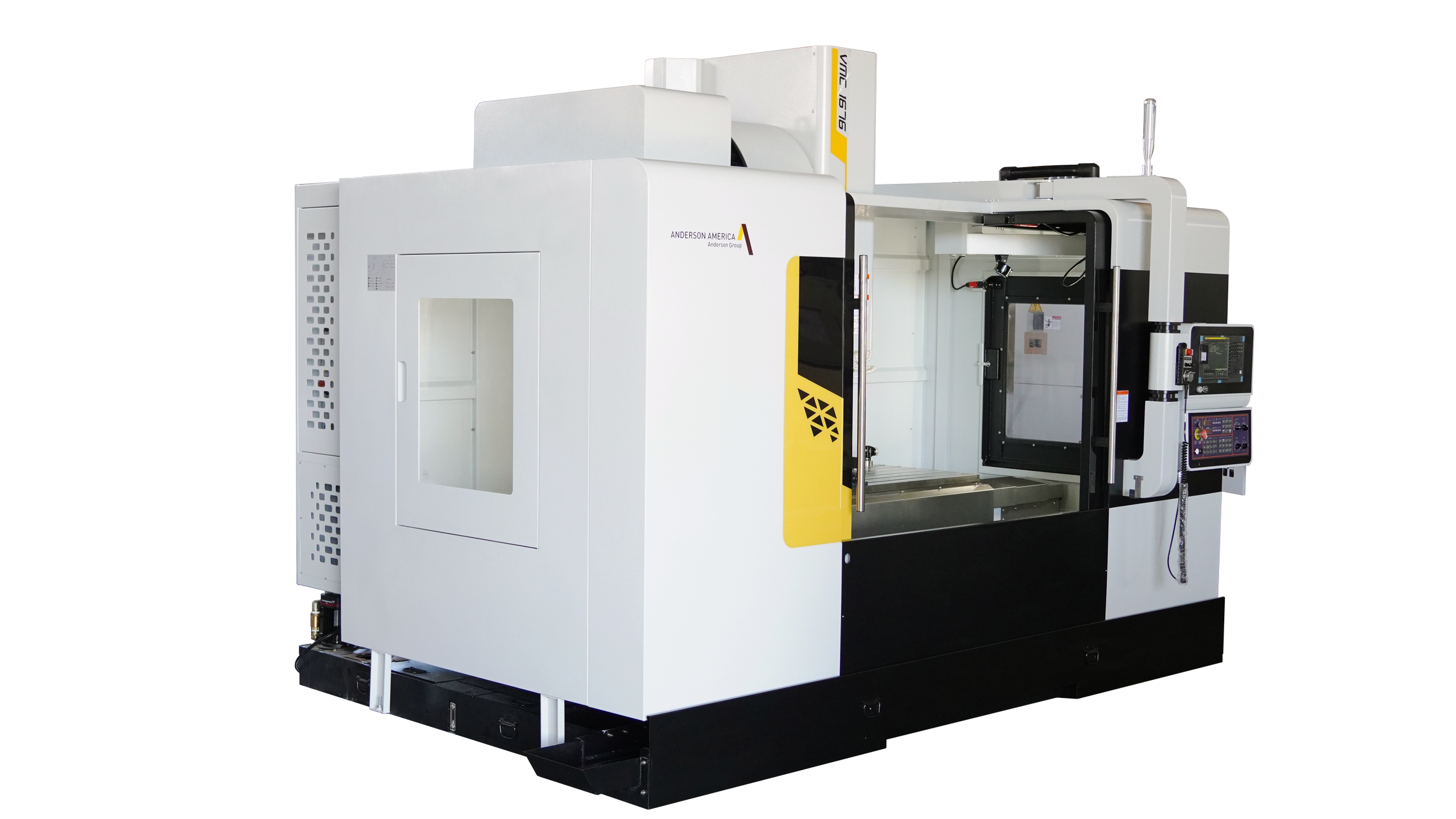

VMC Series

Models: 1676 • 1876 • 2076

The Anderson CNC VMC Series represents the pinnacle of vertical machining technology. Available in three sizes to match your production needs, these machines combine robust construction with advanced FANUC 0i-MF Plus control systems. From the compact VMC 1676 to the expansive VMC 2076, each model delivers exceptional precision, reliability, and productivity for demanding manufacturing applications.

Table Size

1700-2100mm

X-Axis Travel

1600-2000mm

Max Load

1800-2400 kg

Tool Capacity

24-36 Tools

VMC Series Manufacturing Excellence

Explore the precision engineering and build quality of our VMC Series

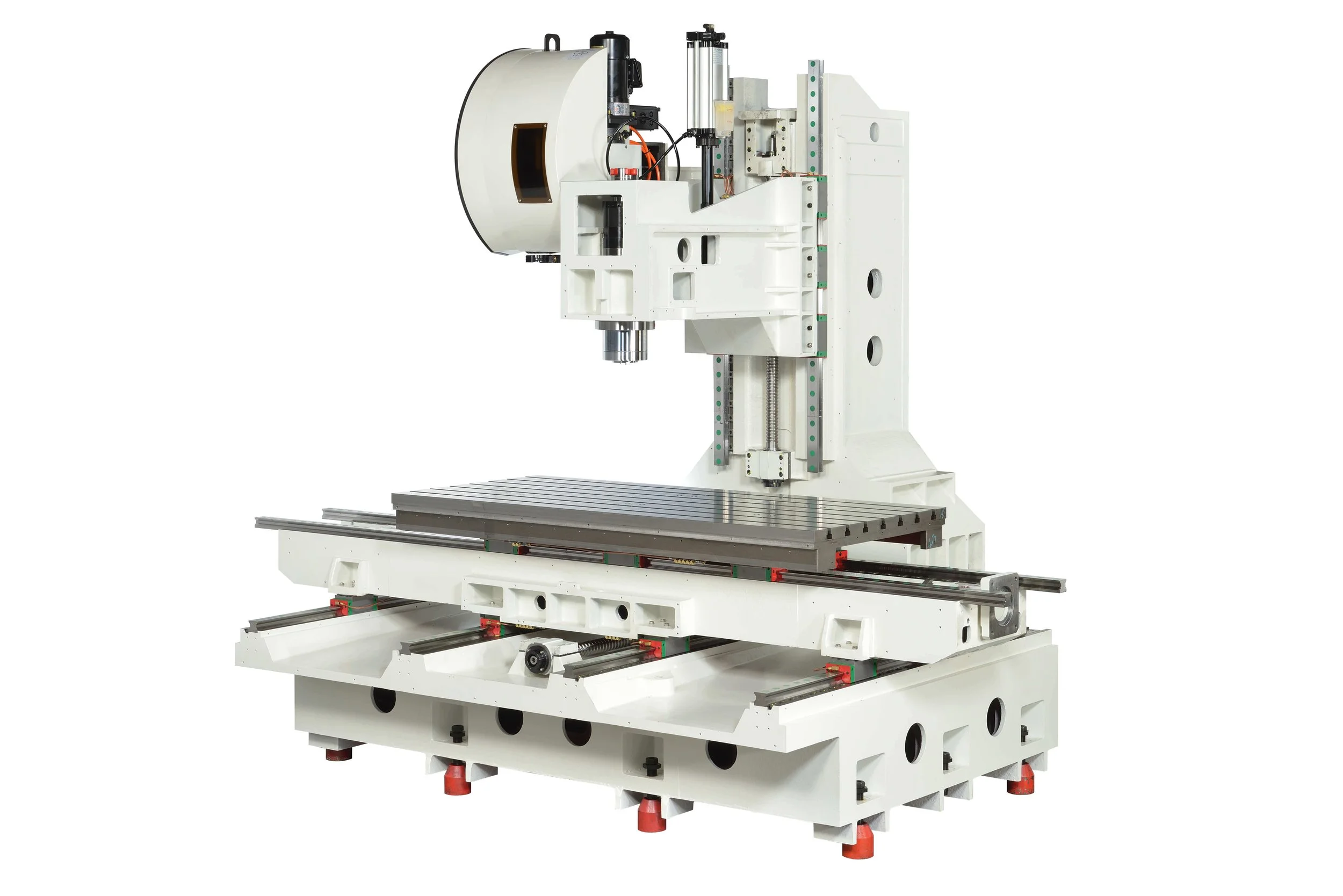

VMC 1676 Base

Heavy-duty cast iron construction provides exceptional stability and vibration dampening

4-Way Control Panel

360-degree swivel control for optimal operator positioning and efficiency

VMC 2076

Our largest model with 2000mm X-axis travel for maximum capacity

Production Floor

State-of-the-art manufacturing facility ensuring quality at every step

FANUC 0i-MF Plus

Industry-leading control system with advanced features and reliability

VMC 1676 Complete

Fully assembled VMC 1676 ready for production with all premium features

Key Features & Capabilities

FANUC Control System

Industry-leading FANUC 0i-MF Plus control provides reliable operation, advanced programming capabilities, and seamless integration with automation systems.

High-Speed Spindle

Powerful direct-drive spindle delivers exceptional torque and speed for efficient material removal across diverse applications.

Automatic Tool Changer

Fast and reliable arm-type ATC system with bi-directional rotation minimizes non-cutting time and maximizes productivity.

Precision Linear Guides

High-quality linear guides on all axes ensure smooth motion, excellent rigidity, and long-term accuracy retention.

Thermal Stability

Advanced thermal management including spindle cooling and temperature compensation maintains accuracy during extended operation.

Chip Management

Efficient chip removal system with dual augers and high-flow coolant ensures clean work area and extended tool life.

| Feature | VMC 1676 | VMC 1876 | VMC 2076 |

|---|---|---|---|

| Table Size | 1700 x 760mm | 1900 x 760mm | 2100 x 760mm |

| X/Y/Z Travel | 1600/760/700mm | 1800/760/700mm | 2000/760/700mm |

| Max Table Load | 1800 kg | 2100 kg | 2400 kg |

| Rapid Traverse | 24/24/24 m/min | 24/24/24 m/min | 24/24/24 m/min |

| Machine Weight | 8700 kg | 9100 kg | 10000 kg |

| Floor Space (LxW) | 4610 x 3470mm | 4970 x 3470mm | 5440 x 3470mm |

Technical Specifications

Engineered for Excellence

The VMC 1676, 1876, and 2076 series represents the pinnacle of vertical machining technology. Built with premium components and backed by Anderson CNC's commitment to quality, these machines deliver exceptional performance for demanding production environments.

Robust Construction

Heavy-duty cast iron construction with thermally stable design ensures long-term accuracy and minimal vibration during high-speed operations.

Precision Engineering

FANUC 0i-MF Plus control system paired with high-precision ballscrews and linear guides deliver positioning accuracy of ±0.008mm.

High Performance

Powerful spindle motors up to 15kW with speeds reaching 15,000 RPM enable efficient machining of various materials from aluminum to hardened steel.

Quality Control

Every machine undergoes rigorous testing and quality checks including laser calibration and ballbar testing to ensure peak performance.

Service Support

Factory-trained technicians provide comprehensive installation, training, and ongoing support to maximize your machine investment.

Fast Delivery

In-stock machines ship within 2-4 weeks from our US facility, minimizing downtime and getting you into production quickly.

Ready to Elevate Your Production?

Experience the precision and performance of Anderson CNC's VMC Series. Our team is ready to help you find the perfect solution for your manufacturing needs.

Fast Delivery

In-stock machines ship within 2-4 weeks from our US facility

Expert Support

Factory-trained technicians provide installation and training

Financing Available

Flexible financing options to fit your budget and cash flow

Warranty Coverage

Comprehensive warranty with extended coverage options available