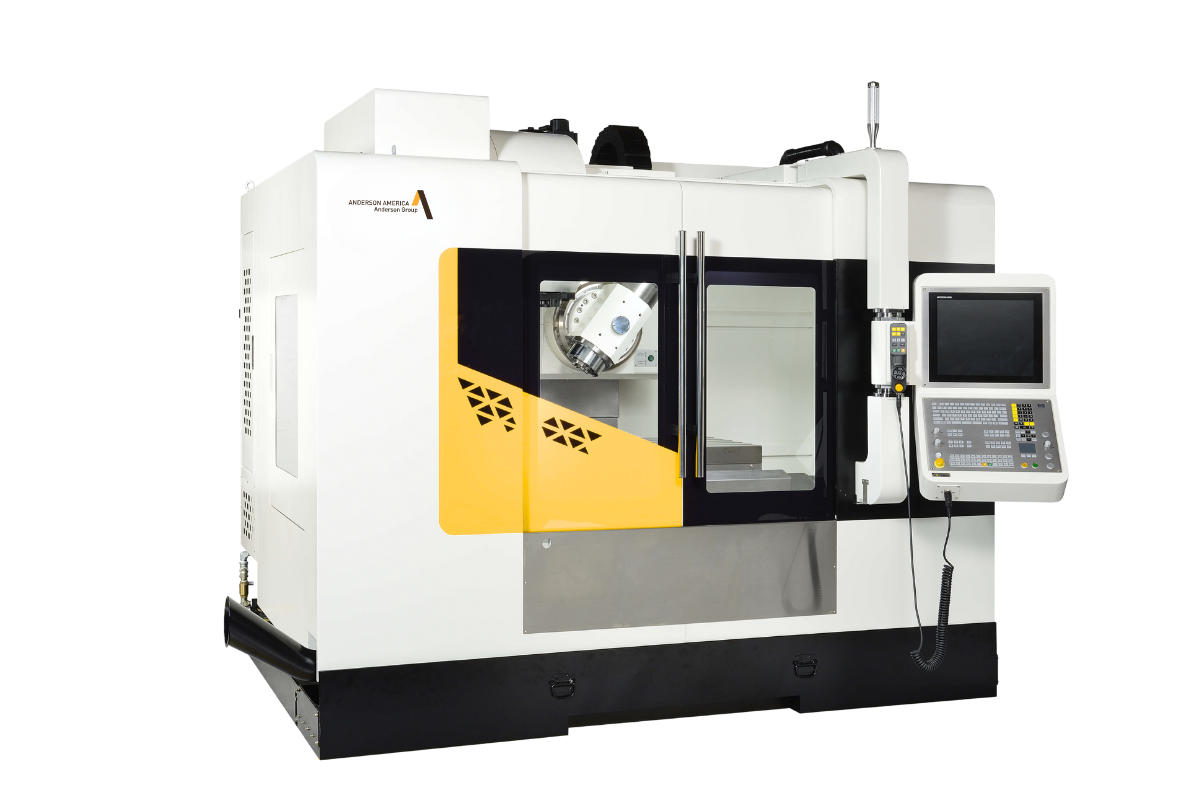

FUV Series

Models: 170 • 200 • 250 • 320 • 400 • 500

The Anderson CNC FUV Series delivers exceptional 5-axis machining capability in a compact footprint. From the ultra-compact FUV-170 to the versatile FUV-500, these machines offer simultaneous 5-axis motion with FANUC control for complex part production. Perfect for aerospace, medical, and mold making applications requiring superior surface finish and geometric accuracy.

FUV Series 5-Axis Excellence

Discover the precision engineering and advanced capabilities of our FUV Series

FUV-400 Complete System

Full 5-axis capability with Ø400mm rotary table and +30° to -120° tilt range

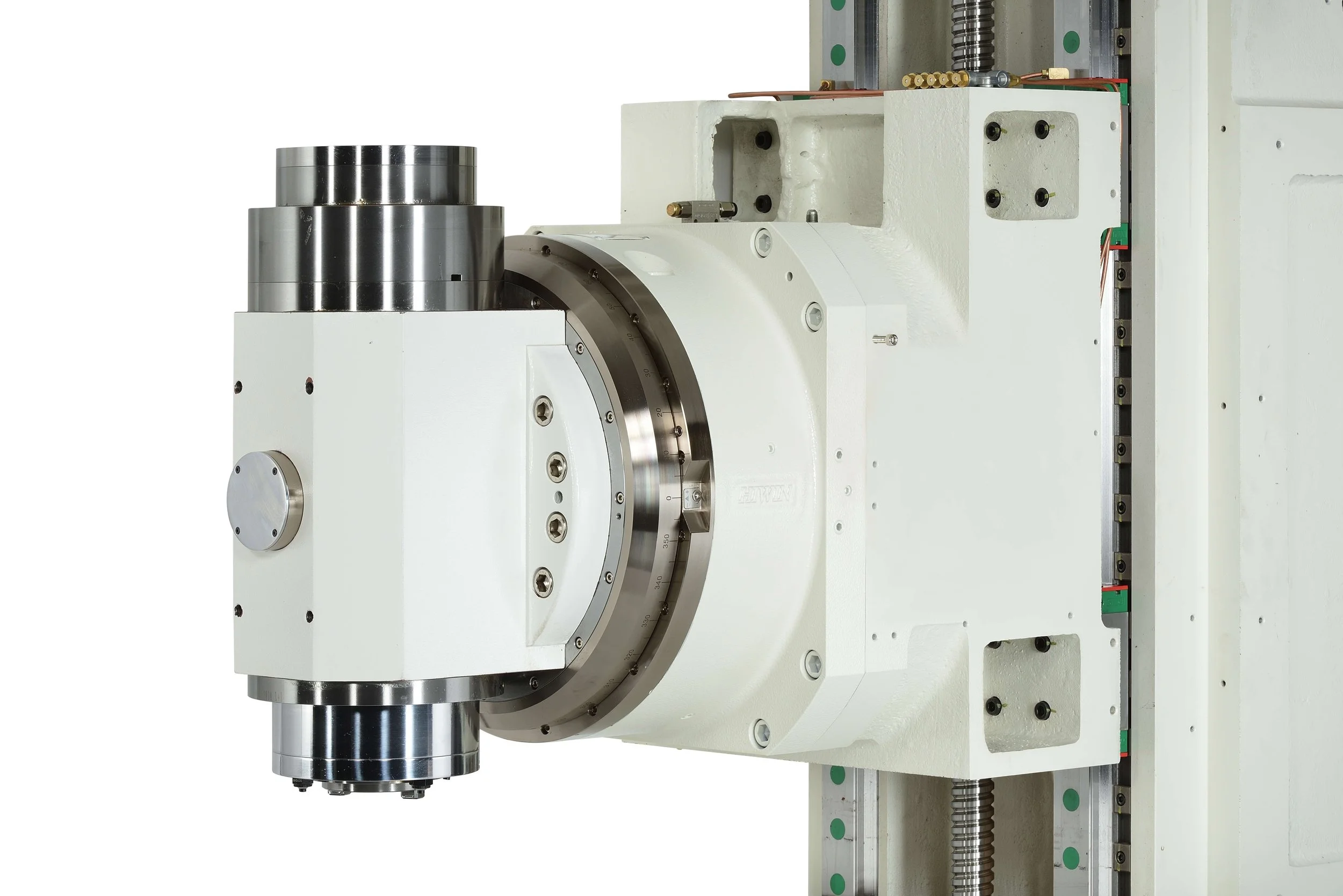

B-Axis Spindle Unit

Direct-drive spindle with precision B-axis tilting for complex geometries

FANUC 5-Axis Control

Advanced FANUC control with simultaneous 5-axis interpolation

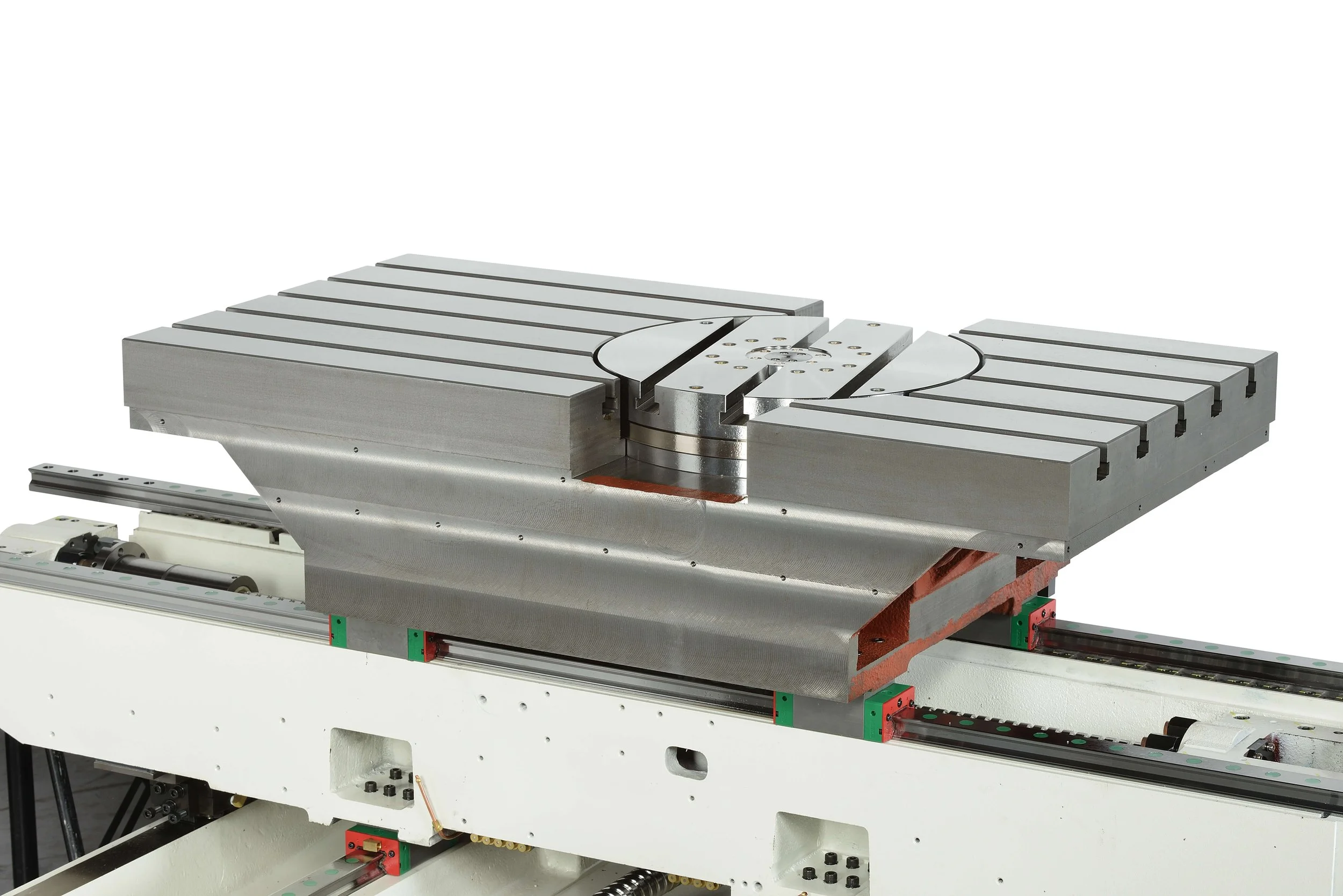

Rotary Table C-Axis

High-precision direct-drive rotary table with continuous 360° rotation

Robust Construction

Heavy-duty cast iron base ensures stability during high-speed 5-axis operations

FUV-170 Compact

Ultra-compact 5-axis solution with Ø170mm table for small precision parts

FUV-500 Large Capacity

Maximum capacity model with Ø500mm table and 300kg load capacity

Complex Part Capability

Ideal for aerospace, medical, and mold making applications

24-40 Tool Capacity

Fast arm-type ATC with random tool selection for minimal downtime

Key Features & Capabilities

Simultaneous 5-Axis

True simultaneous 5-axis machining capability with FANUC control enables complex contouring and optimal tool orientation for superior surface finish.

Compact Footprint

Space-efficient design maximizes workshop floor utilization while delivering full 5-axis capability for complex part production.

High-Speed Spindle

Direct-drive spindle technology delivers exceptional speed and torque for efficient material removal in hard materials and fine finishing operations.

Tilting/Rotary Table

High-precision tilting and rotary axes with direct-drive motors ensure accurate positioning and smooth interpolation for complex geometries.

FANUC 5-Axis Control

Advanced FANUC control with specialized 5-axis functions including TCP control, tilted working plane, and collision avoidance for safe operation.

Tool Management

Fast arm-type ATC with up to 40 tool capacity enables unattended operation and quick changeover between different jobs.

| Feature | FUV-170 | FUV-250 | FUV-400 | FUV-500 |

|---|---|---|---|---|

| Table Size | Ø170mm | Ø255mm | Ø400mm | Ø500mm |

| X/Y/Z Travel | 360/420/465mm | 360/440/465mm | 460/500/500mm | 600/700/520mm |

| Max Table Load | 30 kg | 100 kg | 200 kg | 300 kg |

| Tilt Range | +30° to -120° | +30° to -120° | +30° to -120° | +30° to -120° |

| Machine Weight | 4500 kg | 4500 kg | 6600 kg | 8700 kg |

Technical Specifications

5-Axis Precision Redefined

The FUV Series represents Anderson CNC's commitment to accessible 5-axis technology. With six models ranging from the ultra-compact FUV-170 to the versatile FUV-500, these machines deliver true simultaneous 5-axis capability for complex part production, superior surface finishing, and reduced setup times in aerospace, medical, and precision mold applications.

Compact Design

Space-efficient footprint maximizes floor space utilization while delivering full 5-axis capability. Perfect for job shops with limited space but demanding requirements.

Direct Drive Technology

High-precision direct-drive motors on rotary and tilting axes ensure exceptional accuracy, smooth motion, and zero backlash for complex 3D contouring.

Application Versatility

From aerospace turbine blades to medical implants and complex molds, the FUV Series handles diverse materials and geometries with consistent precision.

Ready to Transform Your 5-Axis Capabilities?

Experience the precision and versatility of Anderson CNC's FUV Series. Our 5-axis experts are ready to help you select the perfect model for your applications.

Quick Delivery

Select FUV models available for rapid shipment from our US facility

5-Axis Training

Comprehensive training programs for operators and programmers included

Application Support

Expert assistance with 5-axis programming and process optimization

Proven Reliability

FANUC control and quality components ensure maximum uptime