DT/AT 750

Models: DT-750 • AT-750

The Anderson CNC DT-750 and AT-750 series represent advanced 5-axis machining technology in a compact, versatile package. With a rotary/tilting table design and spindle speeds up to 30,000 RPM, these machines deliver exceptional precision for complex parts. The DT-750 features dual tilting axes while the AT-750 offers a trunnion-style configuration, both powered by FANUC 5-axis control systems for superior performance in aerospace, medical, and precision manufacturing applications.

DT/AT-750 Precision Engineering

Explore the advanced engineering and 5-axis capabilities of our DT/AT-750 Series

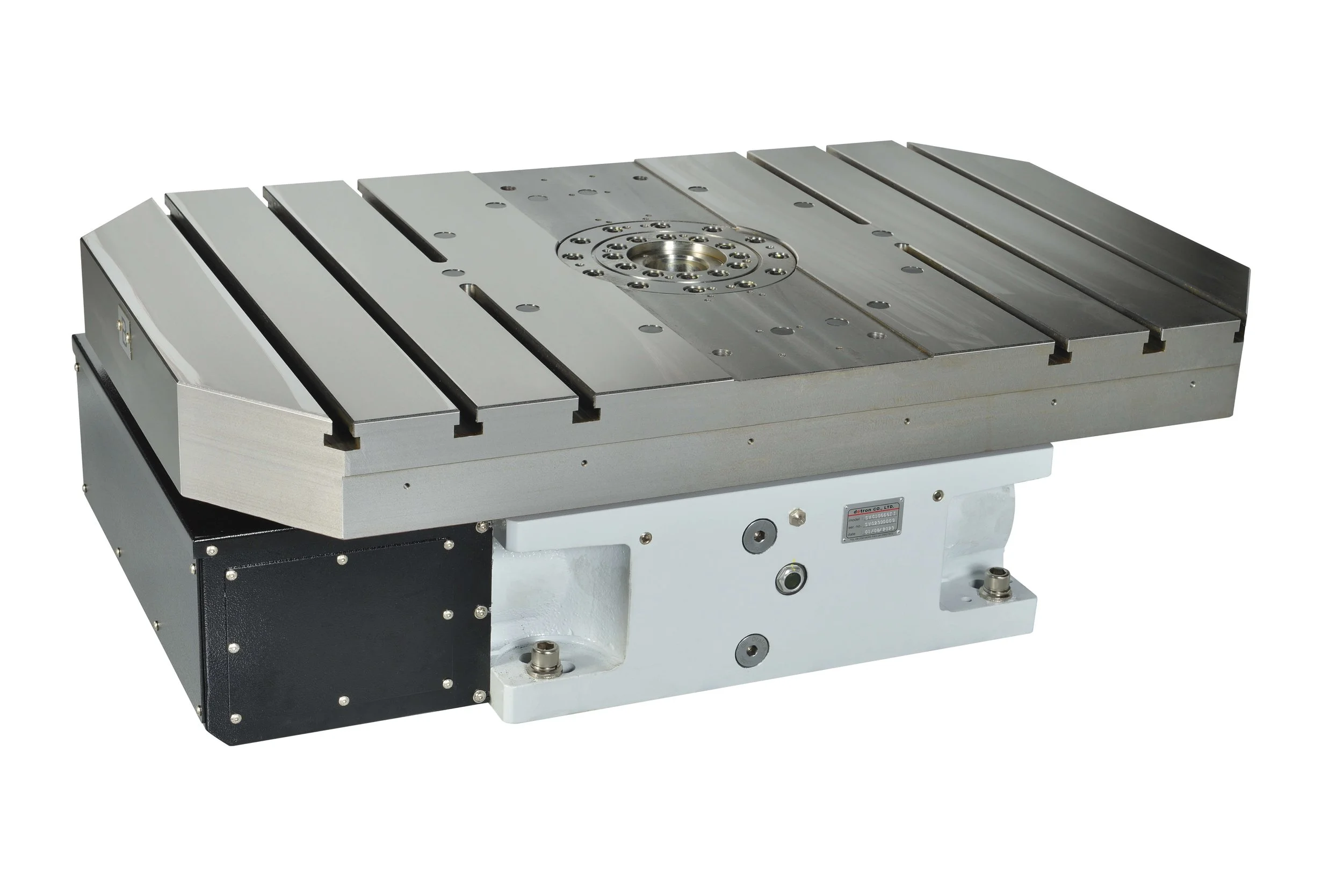

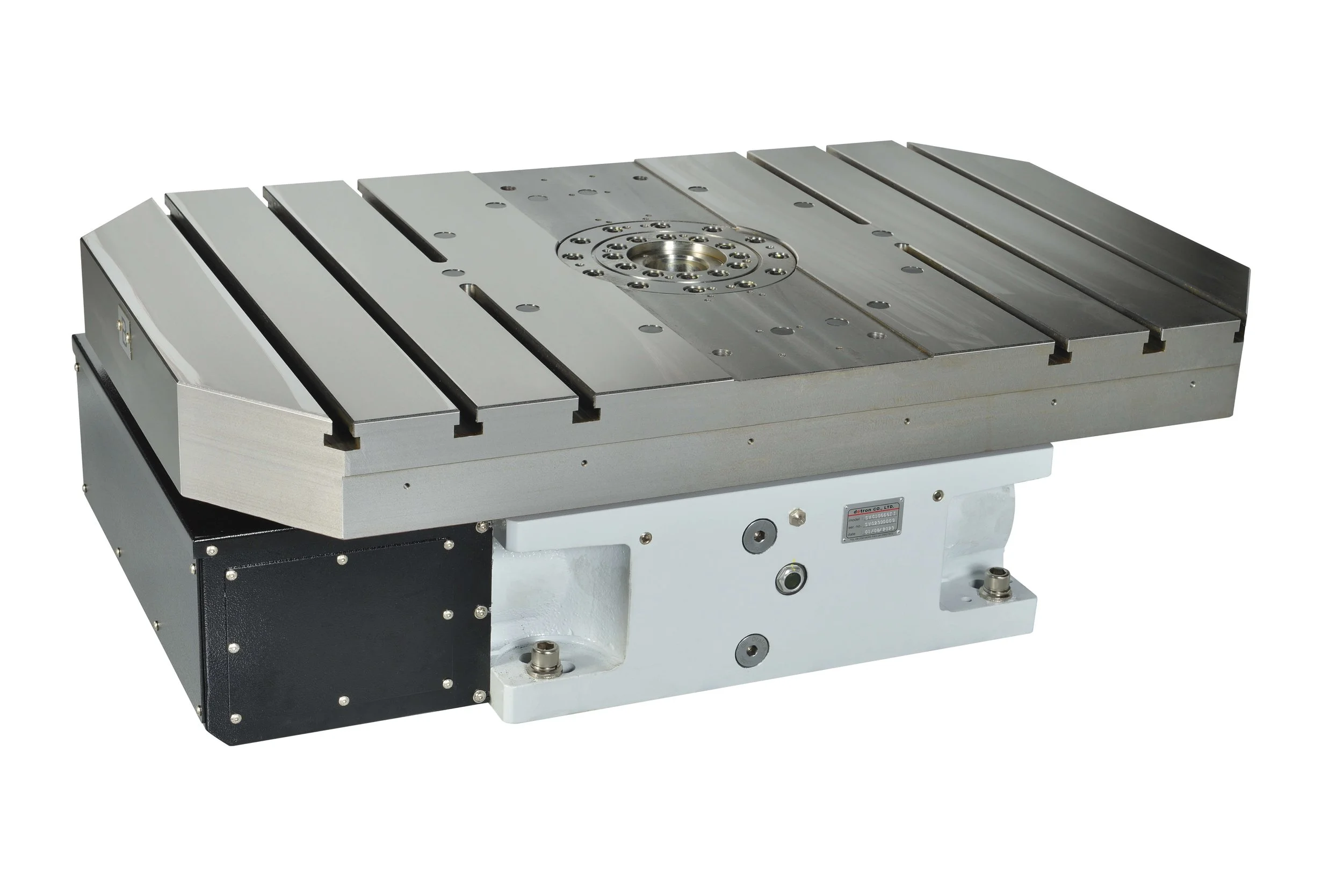

AT-750 Complete

Fully assembled AT-750 with trunnion-style 5-axis configuration

Direct Drive Spindle

Built-in spindle with speeds up to 30,000 RPM for precision machining

Rotary Table

High-precision rotary table with ±120° tilting capability

Robust Construction

Heavy-duty cast iron base ensures stability during 5-axis operations

ATC System

24-40 tool capacity with fast arm-type tool changer

FANUC 5-Axis Control

Advanced 5-axis simultaneous control for complex part geometries

Key Features & Capabilities

5-Axis Simultaneous

Full 5-axis simultaneous machining capability with A-axis tilting ±120° and C-axis continuous rotation for complex part geometries and undercuts.

High-Speed Spindle

Built-in direct drive spindle options from 12,000 to 30,000 RPM enable efficient machining of various materials from aluminum to hardened steel.

Compact Footprint

Space-efficient design with 700x400x500mm work envelope delivers 5-axis capability in a footprint suitable for job shops and production cells.

FANUC Control

Industry-leading FANUC control system with advanced 5-axis capabilities, TCP control, and comprehensive canned cycles for complex operations.

Dual Configuration

Available in DT-750 with rotary table or AT-750 trunnion configuration to match your specific application requirements.

Precision Engineering

High-precision linear guides, precision ground ballscrews, and thermal compensation ensure exceptional accuracy and repeatability.

Technical Specifications

Engineered for 5-Axis Excellence

The DT-750 and AT-750 series bring advanced 5-axis machining capabilities to manufacturers seeking precision, flexibility, and efficiency. Built with premium components and backed by Anderson CNC's commitment to quality, these machines deliver exceptional performance for complex part production in aerospace, medical, and precision manufacturing industries.

5-Axis Capability

Full simultaneous 5-axis control with A-axis tilting ±120° and continuous C-axis rotation enables complex geometries in a single setup.

Precision Engineering

High-precision linear guides, ground ballscrews, and thermal compensation deliver positioning accuracy of ±0.005mm for critical applications.

High Performance

Built-in spindle options up to 30,000 RPM with direct drive technology enable efficient machining of various materials with superior surface finish.

Ready to Advance Your 5-Axis Capabilities?

Experience the precision and versatility of Anderson CNC's DT/AT-750 Series. Our team is ready to help you find the perfect 5-axis solution for your manufacturing needs.

Fast Delivery

In-stock machines ship within 2-4 weeks from our US facility

Expert Support

Factory-trained technicians provide installation and training

Financing Available

Flexible financing options to fit your budget and cash flow

Warranty Coverage

Comprehensive warranty with extended coverage options available